Organizations have a lot of stakeholders to take care of, such as investors, customers, suppliers, employees, trade associations, and communities. However, organizations, especially capital-intensive ones, must take proper care of each of their pieces of equipment too. Effective maintenance of equipment has several benefits – better asset reliability, increased longevity, fewer breakdowns, fewer production disruptions, and reduced maintenance costs, just to name a few.

However, not everyone is able to ensure proper equipment maintenance – some companies are even struggling with it. That being said, let’s take a look at a few useful equipment maintenance tips that can help organizations streamline maintenance management.

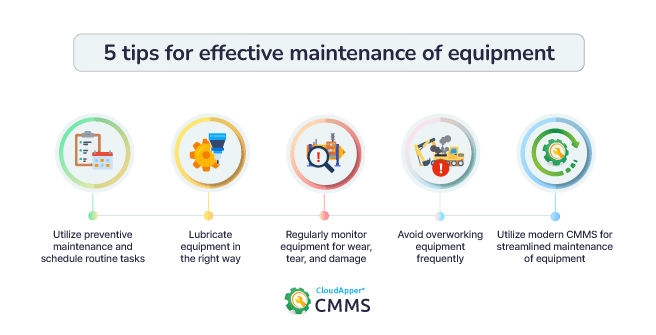

5 tips for effective maintenance of equipment

Utilize preventive maintenance and schedule routine tasks

If you want to ensure effective maintenance of your equipment, then the first step is to implement preventive maintenance. If you already have a preventive maintenance plan, that’s great. However, remember that doesn’t mean that there isn’t room for improvement.

Most pieces of complex machinery and equipment require regular maintenance at specific intervals. This helps them operate efficiently, reduces unplanned machine downtime, and improves reliability. Plan the maintenance tasks based on events or at specific times, for instance, whenever lubrication is required or on a bi-weekly basis.

However, these scheduled maintenance tasks might need to be tweaked based on the operations. For instance, the usage of a conveyor belt might vary depending on the workload. In such cases, reschedule the tasks or try to identify times when the equipment isn’t used. All in all, be prepared for changes and reassign tasks accordingly. All of this helps improve the maintenance of equipment effectively.

Lubricate equipment in the right way

Whenever the topic of equipment maintenance comes up, lubrication is nearly always associated with it. That’s because most of the equipment requires lubrication frequently for optimal performance. Moving parts, industrial centrifuges, and other equipment need lubrication to reduce friction, overheating, and to promote smoother operations.

Just lubricating the equipment isn’t enough, though – there’s more to lubrication management. You need to ensure that you’re using the right lubricant that’s appropriate for the equipment, as different types of machinery require different types of lubrication. It might seem complicated, but checking the manuals can provide you the information you need. Moreover, you also need to ensure that you’re not overlubricating the equipment – excess oil buildup can cause issues down the line. Finally, do check for leaks and ensure that the oil seals are cleaned properly every time.

Regularly monitor equipment for wear, tear, and damage

An essential part of the maintenance of equipment is checking the equipment for signs of wear and damage. This is something that can technically fall under the very first point, but it’s crucial enough to be a separate tip entirely.

Heavy-duty equipment is used in harsh conditions or might be overexerted at times – leading to damages or wear and tear. As a result, maintenance teams must always look for any signs of damage such as misalignments, more noticeable noise, vibrations, overheating, etc. If not identified and addressed immediately, these can lead to reduced performance, hamper the equipment’s longevity, and might even cause workplace safety incidents.

Ensure that the equipment receives maintenance frequently and also encourage machine operators to report any discrepancies whenever they notice them – CloudApper’s CMMS software can help with that as operators can notify the maintenance team right from their smartphones.

Avoid overworking equipment frequently

One of the simplest but most effective ways to ensure proper maintenance management is by NOT overworking the equipment. Every piece of machinery is built with certain limitations such as maximum capacity, pressure, temperature, etc. Only operating the equipment without pushing it all the time provides optimal performance. Otherwise, you’ll be experiencing frequent breakdowns, overheating, and even premature death of the machinery.

The limitations are provided in the manual and documentation provided by the manufacturer, and by adhering to the recommendations, you can ensure that the machine isn’t being pushed to its limits.

However, if you know that you have tasks that require higher performance, then simply purchasing heavy-duty equipment that better suits your needs or buying an additional machine of the same type are good options. Doing so will be cheaper than replacing the original one when it dies prematurely.

Utilize modern CMMS for streamlined maintenance of equipment

If you aren’t utilizing a modern and robust CMMS solution like CloudApper’s, implementing the software will streamline maintenance management.

CloudApper is a no-code enterprise mobile apps platform that has several useful solutions that truly ensure digital transformation. CloudApper CMMS has been built using the platform, and you can customize it entirely even without coding skills!

CloudApper CMMS helps with asset repairs, reduces unplanned machine downtime, and improves asset longevity, right from your smartphone. Contact us today!