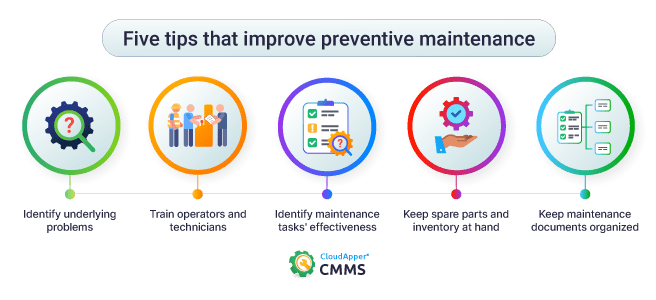

Maintenance management is quite a tricky endeavor. It’s a continuous process, problems can arise anytime, and the organization’s efficiency and performance depend on it. Furthermore, since it’s a constant process rather than just some tasks, maintenance managers need to continuously be updated on the recent news, practices, technology, and training. That being said, let’s take a look at five tips that boost preventive maintenance for equipment.

Five tips that improve preventive maintenance for equipment

Identify underlying problems

Most organizations focus on scheduling maintenance tasks, servicing the equipment, and keeping records of all the activities. However, that’s not all that needs to be done – more minor issues need to be identified and addressed as well. Preventive maintenance means preventing problems that might occur with the equipment and lead to unplanned machine downtime, and it includes both small and large issues. Otherwise, one day, these more minor problems will ultimately lead to production disruptions or worse.

Such smaller and underlying problems can be identified and addressed via inspections, and a robust CMMS solution can help with that. For instance, CloudApper CMMS assists maintenance teams by providing checklists, reminders, and scheduling, helping improve preventive maintenance for equipment in the process.

Train both operators and maintenance technicians

We’ve talked about this point in other articles, but it requires a special mention in this one. Many organizations believe that having the maintenance teams trained is enough for ensuring preventive maintenance for equipment within their facilities. However, unless the machine operators are trained as well, preventive maintenance won’t be effective.

Take the example of a car – no matter how much maintenance it gets, it’ll only work reliably and efficiently if the driver drives it properly. If they drive the vehicle recklessly, accidents, performance issues, or unexpected equipment breakdowns are bound to occur. The same holds true for equipment within facilities – if the machine operators don’t handle them properly, they will malfunction down the line.

Thus, providing training to both the operators and the maintenance technicians is crucial. Operators need to understand how to safely and effectively handle the machinery as well as the causes of minor issues. In contrast, maintenance technicians need to know the ins and outs of the equipment. Moreover, they need to be updated about new practices, methods, or documentation whenever appropriate.

Identify whether maintenance tasks are helping the equipment

No maintenance management plan or approach is perfect – like everything else, there are advantages and drawbacks to all of them. While preventive maintenance is the most balanced and appropriate approach applicable for most organizations, some might be heading towards “over-maintenance.” Over-maintenance does more harm than good as it increases costs, wastes resources, takes up more time than required, and might even hamper the equipment.

Organizations should focus on optimizing preventive maintenance for equipment within their facilities. Instead of just scheduling maintenance tasks, managers should look at the results, identify if they are actually helping the equipment, and make necessary adjustments if required.

Keep spare parts and inventory at hand

This is a crucial tip that helps several organizations with their preventive maintenance efforts. Keeping ample spare parts and inventory at hand is absolutely essential during scheduled maintenance tasks, servicing equipment, replacing parts, and planned downtime. All of this can be managed, ensured, and planned using effective CMMS software solutions like CloudApper CMMS.

However, if it’s not ensured, then scheduled downtime, no matter how effectively it’s planned, will take longer.

Always keep maintenance documents organized, updated, and consistent

Previously, keeping, organizing, retrieving, and updating maintenance management documentation was quite an arduous task. Many organizations are still using spreadsheets to manage maintenance documentation – keeping track of which is a nightmare!

Moving to modern CMMS solutions like CloudApper CMMS drastically improves maintenance management documentation. It helps create, retrieve, manage, and modify maintenance documentation quickly and efficiently – reducing response times and speeding up maintenance tasks.

CloudApper CMMS improves preventative maintenance efforts

A customizable CMMS software that’s made using CloudApper, a no-code enterprise app development platform, CloudApper CMMS is affordable, powerful, and can be used by every organization, regardless of their budget. It costs only $10/user/month. It brings asset management, spare parts & inventory management, vendor management, maintenance scheduling, and an analytics dashboard that helps keep track of activities and provides meaningful insights. The best part is that within the same subscription fee, CloudApper provides several other enterprise applications that help digitize business processes and run businesses via smartphones.

Organizations can contact us now to see how CloudApper CMMS streamlines maintenance management.