Maintenance management is one of the functions that work behind the curtain but is crucial for any organization. It helps equipment run smoothly and reliably, reduces breakdowns and malfunctions, and extends the equipment’s life. Effective asset maintenance management ensures minimal disruptions, reduces unplanned downtime, lowers equipment replacements, and lowers costs. However, it’s easier said than done, as maintenance can be tricky if the tools, practices, and resources aren’t up to the task.

Fortunately, a new year brings new opportunities, challenges, and goals. With that out of the way, let’s dive deeper into some practical tips that can help maintenance managers improve asset reliability.

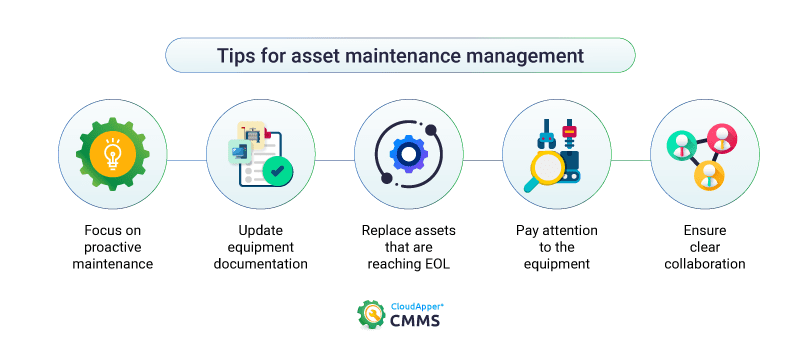

Tips that optimize asset maintenance management

Focus on proactive maintenance

This is one of THE most effective asset maintenance management practices for a reason, and for those that haven’t switched to it yet, it’s high time they do. Preventive maintenance helps schedule maintenance tasks and inspections, reduces unexpected equipment breakdowns, and improves equipment reliability. Organizations utilizing it can vouch for preventative maintenance because it helps reduce bottlenecks, disruptions, and different costs such as maintenance, replacement, and repair expenses.

Update equipment and inventory documentation

Since we’re well into the new year, organizations must update equipment, spare parts and inventory documentation. Listing down operational, problematic, offline assets, and equipment that has reached its end of life, spare parts at hand, and required inventory is a good start.

Keeping these lists updated optimizes asset maintenance management as helps maintenance teams identify which assets require more maintenance, their locations, materials needed for maintenance, and assets requiring replacement. Speaking of replacing assets – let’s move to the next point.

Replace assets that are reaching EOL

When a piece of equipment at your facility is starting to reach its end of life (EOL), it’s time to think of alternatives. While immediately replacing the equipment can be costly and disruptive, organizations can take their time to identify potential options, allocate maintenance resources elsewhere and dispose of assets safely. A machine nearing its EOL can break down or cause more frequent problems, and preventive maintenance can be ineffective in this case. Instead, ensuring reactive maintenance for the asset and reassigning technicians to other assets can be a far more effective strategy, optimizing maintenance efforts.

Pay attention to the equipment’s needs

Asset maintenance management is useless if organizations aren’t paying attention to their equipment’s needs. Are the spare parts being replaced when necessary? Is the machinery being cleaned before the dirt and debris clog the vents? Is the equipment being pushed beyond its limits? Is the machinery receiving ample maintenance? Are inspections done regularly to weed out hidden problems? Even if organizations don’t do any of the above, the equipment will tell them when it’s time – by breaking down, overheating, or malfunctioning! Thus, organizations must do what’s necessary to meet the equipment’s needs.

Ensure clear collaboration

When a process is going on without hiccups, it doesn’t mean that there isn’t room for improvement. Optimizing processes can reduce costs, boost productivity, utilize assets more efficiently and improve asset reliability.

For instance, are machine operators and maintenance teams collaborating effectively? Clear communication helps operators report malfunctions to the maintenance team – reducing response times and providing emergency maintenance if necessary.

A robust CMMS software like CloudApper CMMS helps with that – and more.

Machine operators can easily report malfunctions or breakdowns right from their smartphones with CloudApper CMMS and submit work requests with pictures. Maintenance managers can then inspect the situation and address it appropriately.