While it’s easy to talk about maintenance management, ensuring it is effective can be an arduous task. Several pieces of equipment are spread across different floors or facilities, and if even one of them fails, it will disrupt operations one way or another. A maintenance team’s main objectives are to ensure that the equipment runs without hiccups, disruptions are minimized effectively, and repairs are carried out smoothly. All of this is managed with a robust CMMS solution – as long as it understands the elements of maintenance management.

That being said, let’s look at the elements of maintenance management that must be present within a CMMS app.

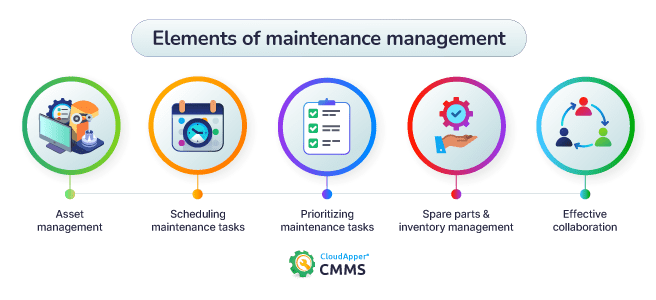

Elements of maintenance management

Asset management

Maintenance management is all about the equipment located within the facilities, which is why asset management is the starting point. Asset management must include all relevant information about the pieces of equipment such as the make, model, serial number, specification, category, location, work history, etc. It’s one of the most common elements of maintenance management and is always present in any given CMMS solution.

However, modern and robust CMMS software solutions like CloudApper CMMS also attach barcodes to the asset’s information, if necessary. When these codes are printed and attached to the equipment, scanning the barcodes using a smartphone or tablet can provide the entire work history along with all the information about said equipment.

Scheduling maintenance tasks

Preventive maintenance scheduling ensures that the equipment receives routine maintenance based on different factors, the most common ones being time and usage. For instance, a conveyor belt might require lubrication every two days, whereas a lathe might require cleaning the spindle tapers after 10000 cuts.

CloudApper CMMS helps plan, schedule, assign, and track maintenance tasks like lubrication management. Regular employees can submit work requests whenever they notice anomalies, and work orders are created by the maintenance managers and assigned to the appropriate technicians.

Prioritizing maintenance management tasks

Maintenance management is important for virtually every piece of equipment, but something that’s just as important is prioritizing the right assets for immediate maintenance. Unfortunately, it’s virtually impossible to ensure maintenance tasks for all pieces of equipment simultaneously, especially with the limited amount of resources available.

Creating a hierarchy based on priority is a crucial element of maintenance management – something that can be done with CloudApper CMMS. For example, assets that are instrumental for production, have high maintenance costs, and need regular maintenance must be prioritized before others to streamline maintenance management processes.

Spare parts and inventory management

Managing spare parts and inventory for carrying out maintenance tasks is one of the more crucial elements of maintenance management. It includes spare parts, chemicals, cleaners, safety equipment, tools, etc. – all of these are required to replace worn-out parts and carry out maintenance tasks effectively.

Without managing spare parts, organizations will fail to get the equipment up and running again in good time, leading to disruptions, bottlenecks, and losses down the line. A flexible CMMS solution like CloudApper CMMS helps keep an ample amount of spare parts and other materials at hand – providing the right components at the right time to the right personnel, helping reduce machine downtime and production disruptions.

Effective collaboration

Maintenance management isn’t limited to assigning the tasks – there must be effective collaboration among the maintenance team members.

CloudApper CMMS, being a cloud-based solution, helps keep everyone on the same page at all times. Maintenance managers can schedule emergency tasks, assign work orders, track progress, and identify anomalies. Technicians carry out the tasks and make notes, if necessary – all of which can be observed by the management using their smartphones or tablets, after which they can provide feedback. This helps reduce clutter and miscommunication and ensures higher productivity by speeding up maintenance tasks.

CloudApper CMMS understands and helps with maintenance management

Built using CloudApper, a no-code enterprise app development platform, CloudApper CMMS is one of the most affordable yet robust maintenance management software solutions available today. It helps organizations reduce unplanned equipment downtime, simplify repairs, and streamline maintenance tasks effectively. However, the best part is that it’s entirely customizable – organizations can modify it to meet their needs by themselves (no coding skills required)! All of these features and more are available for only $10/user/month.

Maintenance managers, technicians, employees, and management can easily collaborate using their smartphones or tablets – making preventive maintenance easier.

Contact us now and streamline your maintenance management efforts.