A maintenance work order is instrumental for maintenance management within any given organization. These documents help carry out routine maintenance tasks, reduce unexpected equipment breakdowns, minimize maintenance costs, and provide clear instructions to the technicians. Work orders can be:

- Created for emergency repairs or maintenance.

- Created for routine maintenance tasks.

- Created for carrying out inspections, audits, or follow-ups.

As can be understood, work orders are crucial for equipment maintenance for several reasons. However, using paper-based systems, spreadsheets, or outdated solutions can make it extremely difficult to organize the information, manage technicians, keep consistent maintenance records, and there are other drawbacks. All of this contributes to higher maintenance costs, lower efficiency, and longer unplanned downtime.

That being said, a robust CMMS solution like CloudApper CMMS can digitize and streamline maintenance work order management – let’s see how.

How CMMS boosts maintenance work order management

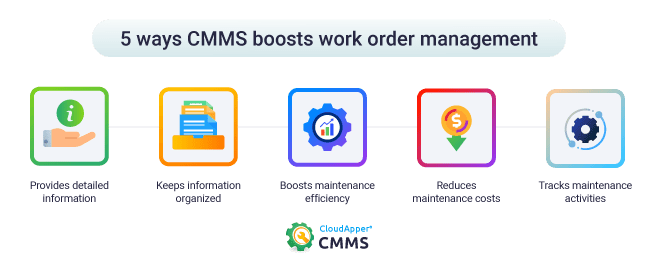

Provides scope for detailed information

Let’s face it – paper-based or outdated systems have several drawbacks: they can house only a certain amount of information. Yes, one can use more paper, but it’s a hassle, whereas one can’t customize outdated systems to include specific information – not all pieces of machinery are the same, and some require more detailed work orders than others.

On the other hand, a modern CMMS can house a massive amount of information within work orders and can be customized to meet the needs of the equipment. In short, a CMMS solution like CloudApper’s can make maintenance work order management more straightforward, more organized, and more efficient.

Keeps maintenance information organized

Work order management can be an arduous task using paper-based or obsolete systems. For instance, a piece of equipment can have several work requests during its lifetime. In addition, maintenance teams need to keep track and organize all of the work histories of different pieces of equipment, something that’s crucial for future reference – but it’s pretty difficult with obsolete systems like spreadsheets or paper-based systems. Just imagine compiling hundreds of maintenance documents related to a single machine – it’s a nightmare!

A cloud-based CMMS solution helps keep all the work history, orders, requests, and other relevant information in a centralized location without requiring any physical storage, something that’s a drawback of paper-based systems.

Boosts efficiency

While work orders themselves improve efficiency, digitizing them with a CMMS solution can take it to the next level. For example, suppose a conveyor belt is malfunctioning and needs to be repaired. The work history needs to be retrieved to check what kind of maintenance the equipment has had to plan for the emergency maintenance – doing so with spreadsheets or paper-based systems can be quite time-consuming.

If software for maintenance management like CloudApper CMMS is utilized, all the maintenance-related information regarding specific equipment is organized automatically. Maintenance teams can scan the barcode on the equipment (assigned by CloudApper CMMS) and retrieve the work history, make, model, specifications, and additional details instantaneously. A CMMS app helps remove the hassle of finding the work history, improves efficiency, reduces response times, and minimizes unplanned downtime.

Reduces maintenance costs

This is an obvious benefit of ensuring maintenance work order management with a modern CMMS solution. Work orders can easily be created, scheduled, and assigned to the appropriate technicians. Compared to obsolete systems, this is far more efficient, and whenever efficiency improves, tasks take less time, processes are optimized, and the maintenance team’s productivity improves.

Moreover, whenever an intuitive maintenance management system is used, regular employees can contribute to the maintenance and easily submit work requests. These requests eventually turn into work orders, helping identify and resolve issues quickly, preventing major problems, and reducing maintenance costs in the process.

Helps monitor and improve performance

Using CMMS software brings several benefits: tracking the work orders, technician performance, and asset downtime. Pending work orders, critical work orders, open work orders, pending work requests – all of these, and more, can easily be monitored with a robust CMMS solution. In addition, maintenance managers can monitor the work order’s progress, provide feedback to the technicians, and receive detailed information from technicians if they identify anomalies. All of this helps monitor maintenance activities as well as improve them over time.

CloudApper CMMS streamlines maintenance work order management and more!

CloudApper CMMS is an affordable, powerful, and modern CMMS software that streamlines maintenance activities, simplifies work orders, helps with asset repairs, and more. Built using CloudApper, a no-code enterprise app development platform, CloudApper CMMS is entirely customizable – users don’t even need to have coding knowledge! In addition, maintenance managers can modify the app themselves to add modules they want and remove the ones that they don’t need – making the app fit their workflow.

Managers and technicians can even use CloudApper CMMS from their smartphones and tablets, making maintenance management possible on the go. The best part is it’s only $10/user/month, and for the same fee, subscribers get access to unlimited apps thanks to CloudApper’s marketplace – all of which can be customized to fit their needs.

Contact us now to streamline work order management, asset repairs, and more.